Howell Laboratories, Inc.

Membrane Air Dehydrators

Remove moisture from the air stream by passing the incoming wet air through an array of membrane modules. Solid contaminants and oil aerosol are removed by mechanical filtration.

Showing all 3 results

-

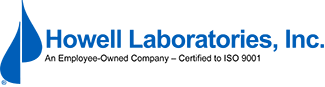

Model 6995 Mk I, IA, II, III, IV Membrane Air Dehydrator

$0.00Designed for continuous, automatic operation. Moisture is removed by an array of BEKO DRYPOINT™ membrane modules. Solid contaminants and oil aerosol are removed by mechanical filtration.

- The industry standard in membrane air dehydration.

- Integrated Condition Assessment System (ICAS) Equipped

- Air capacity to 20 scfm.

- -40° F dew point is recommended for shipboard electronics air.

-

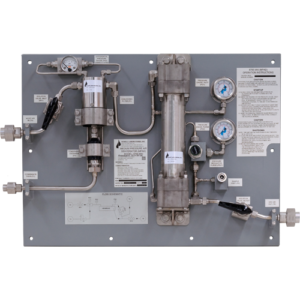

Model 8785 Mk I Medium-Pressure Air Dehydrator

$0.00A self-contained unit designed for continuous, automatic operation. Particulate matter and aerosols removed by a coalescing filter. Then the filtered wet air is passed through a membrane module to remove moisture, resulting in an ISO 8573.1 Class 1, 3, 1 rating.

- Provides clean, dry air at medium pressure (200 psig) for functions such as Diesel engine controls.

- Manual startup – automatic operation.

- Membrane reliability and simplicity, with ultra-low maintenance.

-

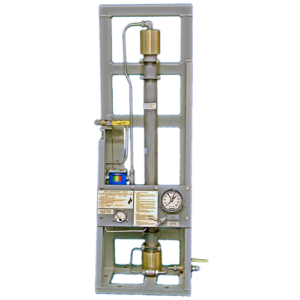

Model 7005 Mk I Air Dehydrator

$0.00Provides clean, dry air for use in shipboard dental operating rooms. Fully automatic and operates with very little maintenance. Includes a coalescing filter (removes 100% of 0.03 micron or larger diameter solids and liquid particles), a membrane dehydrator, and upstream and downstream isolation valves.

- Provides clean, dry air for shipboard dental operating room.

- To 7 scfm dry air.