Shipboard disinfection needs can challenge even the most safety-focused programs. How can you replace costly chemicals that are dangerous to handle, difficult to procure and bulky to store with a hazard-free system that works better and costs less to operate? Howell Laboratories, with its partner MIOX, offers a technological approach that disinfects billions of gallons of drinking and recreational water, daily, for maritime, municipal and commercial industries, worldwide. These systems have capabilities, benefits and features unrivaled in the industry.

We will show you how the MIOX systems can be used for all of your chlorine based disinfection needs, including surface disinfection, pools and spas and potable water.

New technology to generate on site and on demand

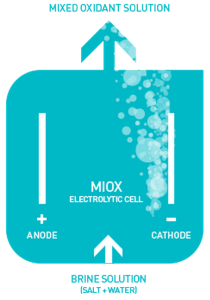

At the heart of the system is a highly developed, patented electrolytic cell requiring only water, electricity and salt to generate all the disinfection chemicals required. It is capable of producing unique chlorine based, mixed-oxidant solution (MOS) chemistry, a highly effective, yet environmentally benign, disinfectant. The presence of a second oxidant in the solution, which coexists for 24–48 hours after generation, provides dramatically increased efficacy, but the MOS can be monitored and controlled with the same ease as older, chlorine-based systems. MOS has a broad range of applications, including:

At the heart of the system is a highly developed, patented electrolytic cell requiring only water, electricity and salt to generate all the disinfection chemicals required. It is capable of producing unique chlorine based, mixed-oxidant solution (MOS) chemistry, a highly effective, yet environmentally benign, disinfectant. The presence of a second oxidant in the solution, which coexists for 24–48 hours after generation, provides dramatically increased efficacy, but the MOS can be monitored and controlled with the same ease as older, chlorine-based systems. MOS has a broad range of applications, including:

- Drinking water: MOS chemistry complies with all EPA, IMO,WHO and CDC standards for safe drinking water

- Recreational water: MOS solution also achieves a better,more rapid kill on a broader range of microorganisms when compared with hypochlorite, allowing clearer water, lower odor and no stinging eyes for pool users.

All MIOX onsite generators are EPA certified for chlorine production and NSF 61 certified.

Learn More: What is MIOX?

Learn More: Certified NSF

Proven biofilm removal

Biofilm is an invasive substance that naturally forms throughout water distribution lines. Biofilm shelters disease-causing microorganisms, shielding them from chlorine disinfection.

Furthermore, it exerts an oxidant demand, consuming disinfectant and requiring higher doses for even basic biological control. Obviously, controlling biofilm is critical to any effective recreational or drinking water disinfection program, but biofilm is resistant to chlorine, and is difficult to remove once initial adhesion occurs. Fortunately, MOS chemistry controls biofilm better than other existing chemistries. This effectiveness has been extensively tested, and is attributed to the presence of hydrogen peroxide in the MIOX system. It is this combination of oxidants that makes the system excel.

Learn More: Biofilm Removal Synopsis

Better against Legionella

MIOX chemistry disinfects more powerfully than hypochlorite alone. This proven advantage is derived from reactive oxidant species in solution with hypochlorite, which coexists with hydrogen peroxide for 24–48 hours after generation. In recent tests, after only a 10-minute exposure to the MIOX solution, all traces of the legionalla bacterium had vanished.

Learn More: MIOX and Legionella Control

Learn More: Microbial MOS vs HYPO Comparison

No hazardous chemicals or by-products

On-site generation replaces traditional chemistries that are inherently dangerous to

handle. Howell/MIOX systems use no hazardous chemicals in the disinfection of chemicals. At a generated concentration of 0.45%, there is no need for hazmat planning and reporting, as the solution is safe to handle.

Positive return on investment

By analysing typical industry costs, on-site generation can immediately reduce the cost of your disinfectant by 75% when compared to current chlorine container systems.

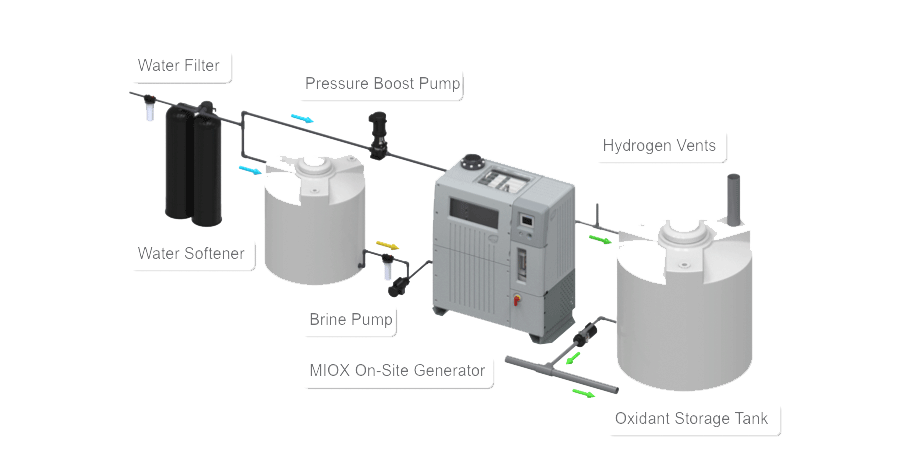

Modular approach to design

Available installation space on cruise ships is always at a premium, so the system is designed to be modular. All tanks and components are individual units, allowing

optimal placement for the maintenance, expansion and even replacement of legacy equipment. Systems also interface with existing control systems.

Water Conditioning Equipment

Feed water to the unit must be conditioned for optimal system performance. This includes filtration, removal of calcium carbonate, control of temperature, and control of pressure. In some installations, this equipment will not be required.

Brine Generation

Salt is the primary feedstock to the system and is necessary for electrolysis. Dry salt is stored in a tank that also serves as the brine generator. A brine filter removes particulate matter from salt that could clog the electrolytic cell. An optional brine pump assists with transfer of brine to the system.

Oxidant Storage

Once the disinfectant is generated, it is stored in a tank for injection into the water supply. Storage tanks are typically sized for 12 to 24 hours’ worth of storage. The level in the tank is controlled by a either a mechanical level switch or a pressure transducer. When the controller indicates a low level, the on-site generator is turned on to produce more disinfectant. When the switch indicates a high level, the on-site generator is turned off. The evolution of hydrogen gas is also managed in the oxidant tank. We can offer both liquid barrier hydrogen safety systems and dilution air systems to safely diffuse and vent hydrogen to the atmosphere.

Injection

Disinfectant is injected into the water supply at rates appropriate for treatment goals. Various methods of injection can be employed, including chemical metering pumps, venturi injectors, and centrifugal feed pumps. These can be adjusted manually or via a 4-20 milliamp input. Injection can be flow-paced or controlled off of chlorine residuals.

To size a generator using our Calculator click here: Chlorine Demand per Day Calculators

Engineered for maritime use

Howell has a proven maritime record as well, having supplied MIOX systems for treating potable water on all the largest US Navy ships for over a decade. The company truly understands the environmental, safety and reliability demands placed upon shipboard equipment.

Overall, a safer, more cost-effective and environmentally responsible solution.

The risks of using ineffective water treatment are real. Howell/MIOX on-site generation of disinfectant replaces the need to purchase, transport and store dangerous chemicals, and provides a safer, more cost-effective and environmentally responsible system.